Application:

Sheet, Film, Plates

Plastic Processed:

PET

Condition:

New

Screw Design:

Double-screw

Twin Screw Type:

Co-rotating Parallel Twin-screw

Screw Material:

38CrMoALA

Screw diameter (mm):

75

Screw L/D Ratio:

33:1

Screw Speed (rpm):

38 rpm

Showroom Location:

Egypt, Canada, Italy, Pakistan, India, Russia, Malaysia

Voltage:

380-415V

Dimension(L*W*H):

20*3*3m

Power (kW):

150

Weight:

5000kg

Warranty:

1.5 years

Key Selling Points:

Multifunctional,Automatic, High productivity

Applicable Industries:

Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Home Use, Construction works , Food & Beverage Shops

Marketing Type:

PET plastic packaging sheet machine

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty of core components:

1.5 years

Core Components:

Bearing, Motor, Pump, Gear, PLC, Engine, Gearbox, Screw

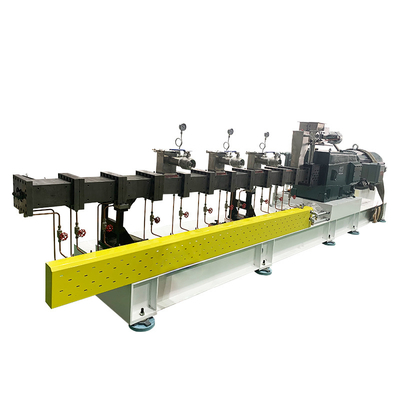

Name:

twin screw extruder for plastic sheet making

raw material:

PET

output:

350kg/hour

Processing Type:

Exturding Machine

producing speed:

3-6m/min

Usage:

Producing PET plastic sheet

colour:

according to customer

Inverter:

ABB

products width:

1200mm

Final product thickness:

0.25-2mm

After-sales Service Provided:

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Egypt, Canada, Italy, Pakistan, India, Russia, Malaysia, South Korea

Zertifizierung:

CE

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!